Mission Builders Foundation wall

FP Ultra Lite Foundation Insulation Panels Tough yet light weight, prefabricated polystyrene insulation panels are pre-coated with an attractive pebble embedded in a polymer modified cementations coating. Constructed of 2 in. thick rigid foam insulation, the panels will insulate, protect and dress up any exposed foundation..

Dolores House Beginning of Styrofoam Blocks

Sheet metal shop bent 10-ft. long Z sections. One-inch vertical leg gets nailed to the bottom 2-by plate, through the 1 in. foam. Middle, "horizontal" leg that is not horizontal covers the thickness of foundation foam, and the last leg extends well into the ground. Just needed hand brake and shears to work the corners in the field.

Meet Saskatchewan’s First Passivhaus Insulated concrete forms

FP Ultra Lite Foundation Insulation Panels tough yet light weight, prefabricated polystyrene insulation panels are pre-coated with an attractive acrylic based cementations coating which is bonded to the. Constructed of 1.5 in. thick rigid foam insulation, the panels will insulate, protect and dress up any exposed foundation..

Foundation Foam Foundation Isolation Canada Engineered Fabrication

11 products in STYROFOAM Board Insulation Compare STYROFOAM R-5, 1-in x 4-ft x 8-ft Residential Sheathing Faced Polystyrene Board Insulation Model # 12086059 Find My Store for pricing and availability 8 Compare STYROFOAM R-3.9, .78-in x 4-ft x 8-ft Residential Sheathing Faced Polystyrene Board Insulation Model # 12031499 Find My Store

Styrofoam Insulation Exterior Basement Walls Openbasement

Since its discovery in 1941, Styrofoam™ Brand XPS Insulation has a long and rich heritage as a sustainable building product, insulating to meeting core thermal, moisture, air and vapor performance requirements through its rigid foam board technology. Low-GWP Styrofoam™ Brand XPS Insulation is now grey and offers a 94% reduction in embodied carbon.

The Benefits of Insulated Concrete Forms (ICF) Foundations TC Legend

When built with Insulated Concrete Forms (ICFs), foundation forms remain in place and provide insulation on each side of the concrete. How much more does it cost more to build foundations with ICFs? Typically, a basement built with ICFs will cost a little more than a comparable concrete or block foundation.

EPS pods and waffle raft slabs blog Expanded Polystyrene Australia

All exterior foundation insulation materials must be approved for below-grade use. Only three types qualify, including extruded polystyrene, expanded polystyrene, and rigid mineral fiber panels. The FoundationPRO, "one-piece insulated foundation finish system," is made with Neopor, an expanded polystyrene insulation with added graphite.

Game Changing Insulated Foundations Living Zenith

Built-in insulated web studs every 6-inches with the same strength as standard studs. Patented "BB" High Density Hard Points deliver 450lbs. of pullout strength for attaching heavy fixtures such as cabinets. The patented BuildBlock interlock is the tightest on the market eliminating costly clips, zip ties and other unnecessary costs..

Styrofoam Blocks Foundation Imgkid Get in The Trailer

Insulated concrete forms (ICFs) are the styrofoam foundation forms. They are light, simple, and easy to work with-they simply snap together like lego. They are permanent forms that stay put even after the concrete is poured, and they help insulate the home once the concrete is dry. The forms can be stacked and interlinked to form walls.

Commercial BelowGrade & UnderSlab Insulation Insulfoam

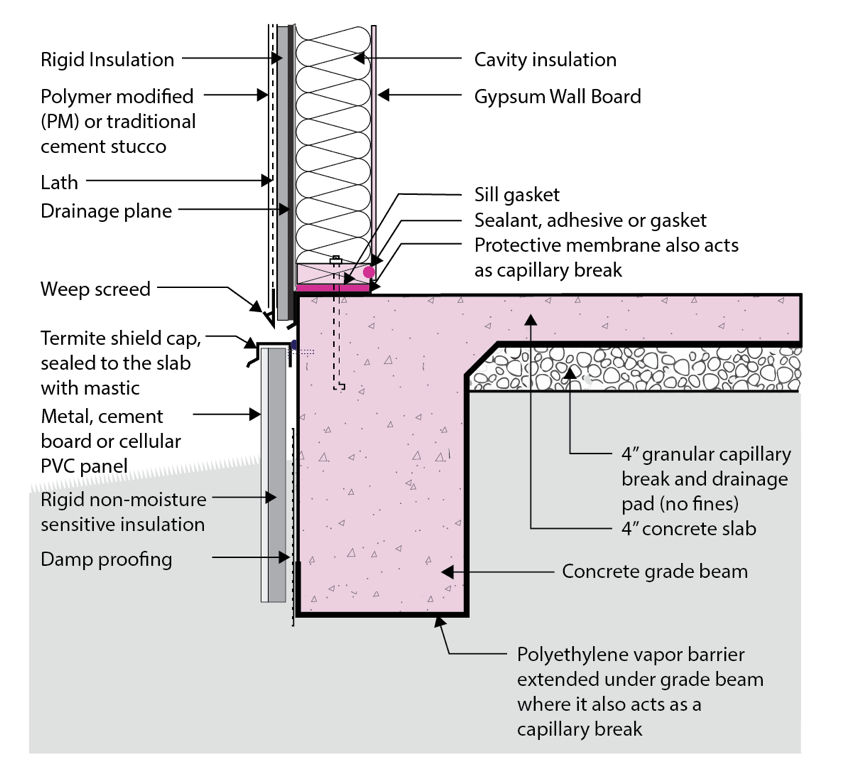

Foundation Insulation Panels Updated: Feb. 21, 2023 Two easy ways to dress up and insulate exposed foundation walls Next Project Family Handyman Insulate and dress up bare foundation walls using coated rigid insulation. Use termite resistant insulation for termite infested regions. By the DIY experts of The Family Handyman Magazine

Dolores House Styrofoam Blocks Completed

Insulate a new foundation wall or an existing foundation wall by adding rigid insulation to the exterior side as follows: Locate underground utilities. Excavate the foundation perimeter. Install a footing perimeter drain pipe to provide adequate exterior drainage. Install damp proofing or a waterproofing membrane on the exterior side of the.

ICF 101 ICF Builder Magazine

Foam enables people all over the world to experience and enjoy photography, whether it's at our museum in Amsterdam, on the website, via Foam Magazine or in our Editions Gallery.Completed in 1716, the building where Foam is situated - Keizersgracht 609 - first operated as a warehouse. In 2002 it became Foam and has since been a hotspot for.

The Benefits of Insulated Concrete Forms (ICF) Foundations TC Legend

Insulation Protection There is no perfect material for covering and protecting exterior foam on foundations. Use metal or plastic reinforcing to strengthen the cement parging on foundation foam boards. The most common approach is to apply a stucco-like "parged" finish with a surface-bonding cement.

This highly insulated foundation assembly in made up of a thickened

Insulating a concrete foundation. A builder in Idaho wonders how to waterproof a foundation wall that will be insulated on the exterior with 2 inches of rigid foam insulation, and whether there is any benefit to fully encapsulating the footing with foam. Image Credit: Nethaniel Ealy

Insulating Exterior Foundation Walls. Foundation Insulation with

Insulated Foundation Finishing System. Unique system simultaneously finishes and insulates exposed foundations. This one-piece solution meets the homeowner's desire to cover the exposed foundation of the home while also providing added insulation, comfort, moisture management and pest control. It provides a beautiful, finished appearance that.

What Should I Know About Styrofoam™ Insulation?

Insulated concrete form (ICF) is a way to lay a building's foundation using interlocking foam bricks. These hollow polystyrene walls are used to build the outside form of the foundation, and reinforcing rebar is placed inside within the form for added strength. Once the forms are all put in place, concrete is poured in the middle.